80mm Cutter Gooda Maufacturer Customized Products Milling Machine Vertical Cutting

Description

Basic Info.

| Model NO. | VM-1320NC |

| Milling Cutter Structure | Indexable Type |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Precision | High Precision |

| Certification | GS, CE, RoHS, ISO 9001 |

| Condition | New |

| Spindle Taper | Bt50 |

| Spindle Speed | 50-500 |

| Spindle Motor Power | 15kw |

| Worktable Size | 2000*1000mm |

| Machine Weight | 12000kg |

| Space | 5.5*2.9m² |

| Machine Height | 2854mm |

| X,Y,Z Axis Motor | 3/3/3 |

| Max Column Width | 1300mm |

| Max Cutting Heigh | 400mm |

| Controller System | Optional,Siemens/Fanuc/Mitsubishi |

| Max Loading Weight | 6000kg |

| Finish Cutter Diameter | 250mm |

| Separate Cutters | Rough & Fine |

| Rough Cutter Diameter | 80mm |

| Transport Package | Steel Box |

| Specification | Customized products |

| Trademark | GooDa Maufacturer |

| Origin | China |

| HS Code | 8459611000 |

| Production Capacity | 600sets/Year |

Product Description

Product Description

MODLE : VM-1320NCCNC Planer Vertical Milling Machine,Automatically measure, Automatically remove chips.CNC GANTRY MILLING MACHINE

Features and applications:

- Automatically measure, automatically processing and excellent surface performance.

- Maintain high accuracy for dimension, squareness and parallelism.

- One loading and one setting needed only is helpful to shorten the preparation time.

- Mainly used for pre-squared steel plate and non-ferrous metal materials for flat surface.

- Machine base with chip removal groove

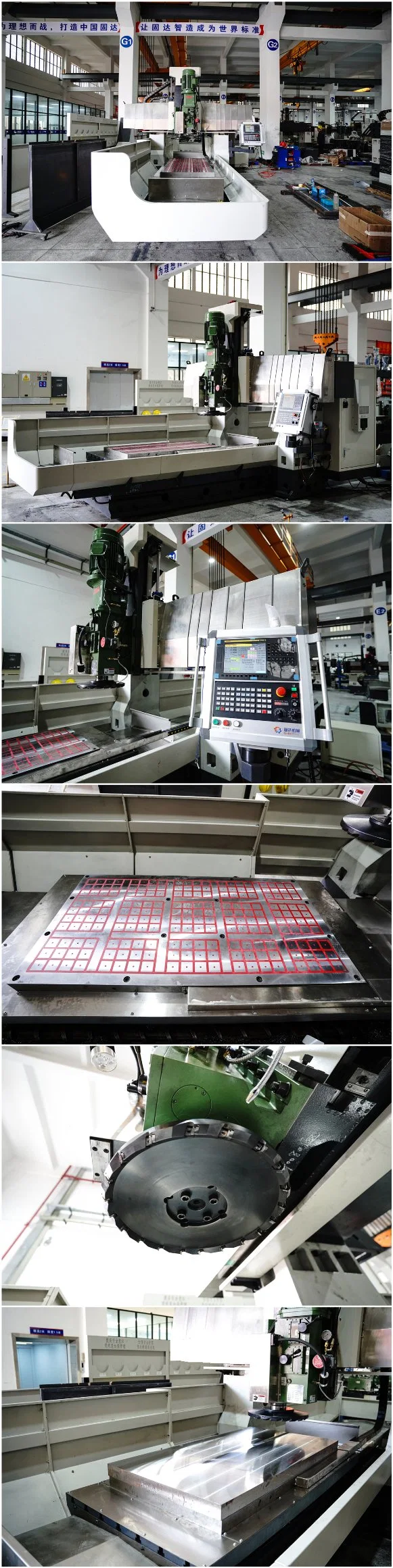

Detailed Photos

VM-1320NC fine and rough integrated vertical double-head milling machineDouble column split structure, excellent rigidityHigh-power gear head for rough milling, ultra-precision belt spindle for fine millingSuper powerful small grid electric permanent magnet table, the killer of "Mahjong material"Fine rough milling cutter, the cutter is saved by 50%, milling instead of grinding!

Manufacturing capacity

Specification

Separate Cutters - one for Rough milling, one for Finish milling

| Item: CNC Gantry Milling Machine | Unit | Model | |

| VM-1320NC | |||

| Cutting Capacity | Control Axis | No. | 4 |

| Maximum length | mm | 2000 | |

| Maximum width | mm | 1300 | |

| Maximum height | mm | 400 | |

| Column width | mm | 1350 | |

| Worktable | Table size | mm | 2000*1000 |

| Max loading weight | mm | 6000 | |

| T-slot size | mm | 22*150*6 | |

| Gear Spindle (Rough milling) | Spindle power | kw | 15 |

| Spindle taper | - | BT50 | |

| Spindle speed | rmp | 50-800 | |

| Cutter diameter | mm | 80 | |

| Belt Spindle (Finish milling ) | Spindle power | Kw | 11 |

| Spindle taper | - | BT50 | |

| Spindle speed | rmp | 50-500 | |

| Cutter diameter | mm | 250 | |

| Feed | X feed speed | mm/min | 8000 |

| Y feed speed | mm/min | 8000 | |

| Z feed speed | mm/min | 8000 | |

| X/Y/Z Motor | Kw | 3/3/3 | |

| Others | Machine height | mm | 2854 |

| Machine weight | kg | 12000 | |

| Space | m | 5.5*2.9 | |

| CNC system | - | FANUC SYSTEM OR Mitsubishi controller OR Siemens System | |

| VM-1320NC Main part | ||||

| Sort | Name | Quantity | Origin | Remark |

| Machinery | Ball screw | 3 | TBI/TaiwanTPI/HIWIN | steady transmission,High accuracy, wear-proof |

Electric permanent magnet sucker | Thales | Famous brand | ||

The milling head | 1 | Taiwan | Famous brand, high quality | |

Bearing | 1 | TPITaiwan TPI | famous brand, High accuracy, High quality | |

Lubricating oil pump | 1 | Baoteng | Famous brand, high precision, high quality | |

| Electrical appliances | NC system | 1 | Taiwan JK | Taiwan famous brand,High accuracy |

Servo motor | 3 | Japan Yaskawa | orld famous brand, high precision | |

Electrical components | 1 | French Schnrider | Famous brand, steady property | |

You can choose FANUC system or MITSUBISHI Controller as you like.*Gooda Milling Machine has full automatic measurement and / tool-setting, automatic tool division and automatic connection cutting, automatic rough cutting and finish cutting.*Gooda will help you reduce setting time and reduce running cost,to increase efficiency.The integrated high rigidity T-shaped bed, double- column structure and crosswise overhangless structure ensure high straightness accuracy and and excellent workability.

Certifications

Manufacturer of CNC duplex milling machines and other series of professional CNC machine tools !!

Packaging & Shipping

Packing and shippingTo be packed in fumigation wooden case or in steel box,suitable for long distance ocean transportation,well protected against moisture and shocks,pressure wetness.

Company Profile

{Workshop}Main products:CNC duplex milling machine,CNC high speed sawing machine, CNC Vertical milling machine,CNC Gantry milling machine, CNC Machining Center, CNC three Axis Chamfering machine,CNC Planar Grinding machine,Plate flipping machine.The application scope of the products includes mold steel,moldbase, aluminum plate,die processing and other metal cutting.After years of research and development and innovation, the products are at the leading level in terms of processing accuracy,machine stabilitym,Ergonomic design and other technical performance. With the continuous improvement of market demand, GooDa has launched six side processing solutions, indirectly promoting the development of China's mold industry.After years of unremitting efforts, the company has obtained dozens of patent technology and software coyright, and has successively passed the ISO 9001 quality management system certification of EU TUV certification body,EU CE product safety certification, intellectual property management system certification,national high-tech enterpise evaluation and other honors.In order to maintain the leading edge of product technology,the company has actively carried out school enterprise cooperation to continuously promote the development of the enterprise while recruiting excellent talents in the industry.Benefiting from the company's innovation and R&D advantages,the company has developed rapidly in just a few years. The existing R&D and production sites have restricted the company's subsequent development, and the space for capacity improvement is limited. For the company's sustainable development in the future, in 2018, GooDa invested heavily in the construction of GooDa machinery's normal headquarters Indusrial Park to support the development of the company's high-end CNC machine tool equipment project, Greatly enhance the company's CNC inteligent equipment capacit.

Let GOODA help you keeping quality at 100%!

{ EXHIBITION }

Every feature,function and configuration of our machinery are made for our customer

FAQ

FAQ:1. What is your minimum order quantity and warranty? MOQ is one set, and warranty is one year.2.What CNC system do you use? FANUC, SIEMENS, MISTSUBISHI etc. It depends on your choice.3.When is the delivery time? Conventional Machines,We will delivery then within 30-45 working days after received your deposit,if some special machines will be some longer.we will give you the answer accordingly.4. What is the package of the machines? Packing: PE bag cover inside+ Plywood box + Steel beam frame.5.How can I choose the most suitable machines ? Please let us know your machining demand or machine size ,we can choose the best model for you , or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .6. What is your trade terms? FOB, CFR,CIF or others terms are all acceptable.7. What is your payment terms ? Payment Terms : T/T 30% advance , 70% before shipment.

The benefits of GOODA maintenance contract (After sales 3 years):

- Basic requirement in a certified QS system

- Guarantee for the accuracy of the measuring and test results

- Calibration, maintenance and, if necessary, repair with just one visit

- Fixed prices with a clear breakdown of costs

- Preventive maintenance helps you avoid expensive faults and ensures a high level of quality that lasts

The maintenance contract includes:

- Travelling time and expenses for our technician

- Maintenance and calibration work

- Small items required for carrying out the specified maintenance work

- Calibration with a corresponding maintenance and test report, allowing the results to be used to demonstrate compliance with national standards

We offer the super six-sided pre-squaring on mold steel plate preparation, producing a milled, squared and chamfered plate ready for production without costly and destructive grinding.2. After sale service, we will help you at once when there is a problem. besides, we will check machine regularly.3. Machines come wired for USA electricity or your local electricity.4. We supply expert installation and training.Don't worry and trust us, we will all here serve for you!!

Prev: Nisen Ljz2

Next: Customized 360mm Polybag Band Paper Pipe Sheet Foil Cutting Machine Automatic Manufacture

Our Contact